The development and expansion of the healthcare industry are heavily reliant on a stable and high-quality power supply. A hospital's power distribution system is a crucial factor in ensuring reliable operations. With advancements in modern technology, hospital power infrastructure has improved significantly. However, as hospitals integrate more electronic medical equipment, they introduce a common challenge: the generation of harmonic distortions that degrade power quality. Medical devices require high-quality power to function correctly, and harmonic distortions can lead to voltage and current waveform distortions, impacting overall power quality. If not properly managed, these distortions can cause operational failures, reduce equipment lifespan, and interfere with critical medical procedures. Addressing power quality issues is essential for hospital administrators and design teams.

Keywords: Hospital Power Distribution System; Medical Equipment; Power Quality; Harmonic Distortion and Mitigation; System Solutions

1. Introduction

The advancement of hospitals and medical facilities requires sophisticated technology to ensure reliable power infrastructure. Hospitals must achieve efficient and stable energy use to reduce operational costs and enhance service quality. Hospital power distribution systems serve as the backbone of medical operations, consisting of various nonlinear and time-variant electrical and medical devices. These devices generate harmonic distortions, which, if left unmitigated, can disrupt essential operations and even compromise patient safety. Conducting thorough analyses and implementing solutions for power quality management in hospitals is critical.

2. Sources and Characteristics of Harmonic Distortions in Hospital Power Systems

Hospital power distribution systems have multiple sources of harmonic distortions, which can be categorized into three main groups: medical equipment, information and communication systems, and electrical appliances.

Medical Equipment

Hospitals rely on a wide range of medical devices, many of which contain power electronics that generate harmonic distortions. Examples include:

- CT Scanners: These devices use high-frequency, high-voltage generators, converting three-phase AC power into high-frequency DC and then back to AC. This process introduces significant harmonic currents, with total harmonic distortion (THD) reaching up to 30%.

- Magnetic Resonance Imaging (MRI) Systems: MRI machines use alternating magnetic fields and radiofrequency pulses, creating harmonic distortions with a THD of around 20%.

- Linear Accelerators (LINACs): These devices, used for radiation therapy, operate with high-frequency power supplies and pulse modulation systems, leading to harmonic distortions reaching 40–50%.

- X-ray Machines: These devices are transient loads with instantaneous power spikes exceeding 60–70 kW. Their rectifier circuits contribute to harmonic distortion levels between 30% and 50%.

Information and Communication Systems

Hospitals increasingly depend on digital systems for medical records, imaging, telemedicine, and real-time patient monitoring. These systems involve thousands of computers and network devices that contribute to harmonic pollution.

- Uninterruptible Power Supply (UPS) Systems: UPS systems are essential for hospitals to maintain power during outages. However, UPS devices using IGBT and PWM technologies generate substantial harmonic currents. A three-phase, six-pulse rectifier UPS system can introduce THD levels between 30% and 40%.

- Network and Telecommunication Devices: Data centers, audio/video communication systems, and telemedicine services operate continuously, generating harmonic distortions.

Electrical Equipment

- Lighting Systems: Fluorescent lighting and LED fixtures generate significant third-order harmonic currents. When connected in three-phase systems, these harmonics accumulate in the neutral wire, increasing the risk of overheating.

- HVAC Systems and Variable Frequency Drives (VFDs): Many hospitals use VFDs for HVAC systems and ventilation. These drives generate substantial 5th and 7th-order harmonic distortions, reducing overall power quality.

3. Impact of Harmonic Distortions on Hospital Power Systems

Impact on Power Networks

Harmonics increase system losses, cause overheating, and can trigger unintended protective device operations. Harmonic resonance can occur when reactive power compensation capacitors match the system’s impedance, amplifying harmonic levels beyond safe thresholds.

Impact on Transformers

Harmonics increase core and copper losses in transformers, reduce efficiency, and lead to excessive heating, which may reduce the transformer’s lifespan.

Impact on Motors and Generators

Harmonic distortions lead to additional motor losses, mechanical vibrations, noise, and harmonic-induced overvoltage, reducing operational efficiency.

Impact on Medical Equipment

Sensitive diagnostic and therapeutic devices can experience erratic behavior, measurement inaccuracies, and unexpected shutdowns due to voltage distortions caused by harmonics.

Impact on Communication Systems

Harmonic distortions induce electromagnetic interference (EMI), degrading the performance of network infrastructure, telemedicine services, and real-time monitoring systems.

4. Power Quality Monitoring and Mitigation Requirements

Power Quality Requirements for Hospitals

Hospitals require high power quality for reliable medical equipment operation. The key characteristics include:

- Stable Voltage and Frequency

- Minimal Harmonic Distortions

- Continuous Power Supply (No Interruptions)

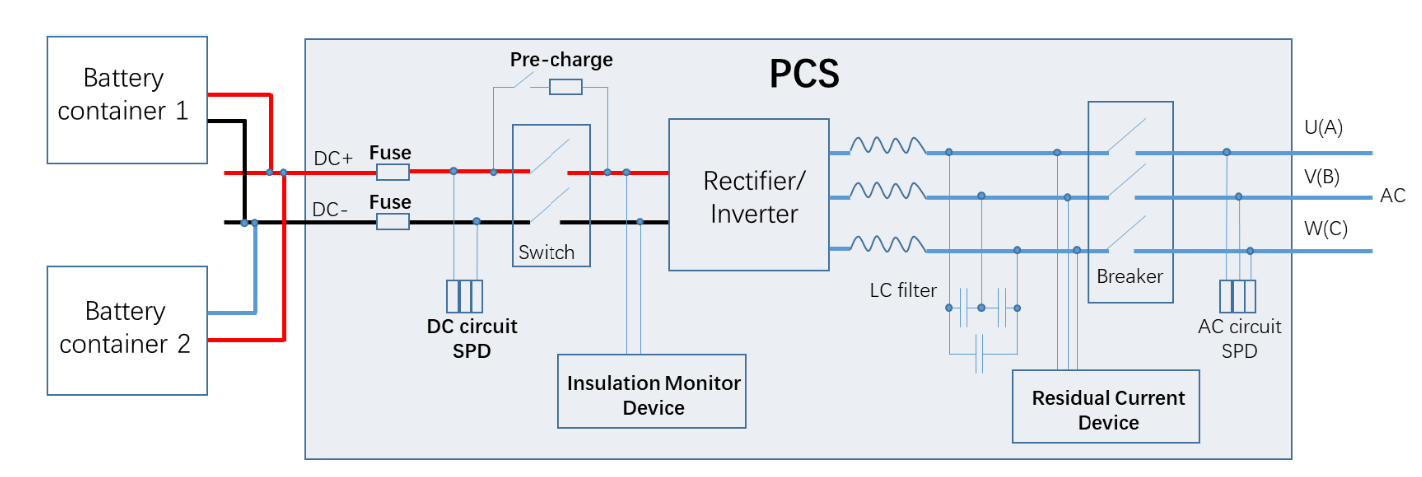

Proposed Power Quality Solutions

- Centralized and Localized Harmonic Filtering: Active and passive harmonic filters should be installed at the main distribution level and at individual loads.

- UPS and Voltage Regulation Systems: Properly rated UPS systems with power factor correction help mitigate harmonic distortions.

- Isolation Transformers: These transformers help reduce the impact of harmonics on sensitive medical equipment.

- Smart Power Monitoring Systems: Real-time monitoring enables hospitals to detect power quality issues before they cause failures.

5. Hospital Power Quality Monitoring and Mitigation Solutions by Sunco International Inc.

Solution Overview

Sunco International Inc. offers comprehensive power quality monitoring and mitigation solutions designed to enhance the reliability of hospital power distribution networks. Our solutions include:

- Real-time power quality monitoring

- Harmonic filtering systems

- Voltage stabilization solutions

- Predictive maintenance using AI-powered analytics

Features of Our Power Quality Management System

✅ Real-time Monitoring – Live tracking of voltage, current, harmonics, and power factor ✅ Automated Alerts & Reporting – Instant notifications for abnormal power quality events ✅ Harmonic Mitigation – Active and passive filters to ensure compliance with IEEE 519 standards ✅ Cloud-Based Analytics – Remote monitoring and predictive maintenance ✅ Energy Efficiency Optimization – Identifies power waste and optimizes hospital power usage

6. Case Study: Power Quality Improvement in a Large Hospital

Background: A major metropolitan hospital experienced frequent disruptions due to voltage fluctuations and harmonic distortions.

Solution:

- Installed harmonic filters to mitigate 3rd, 5th, and 7th order harmonics.

- Deployed real-time power monitoring with predictive analytics.

- Optimized power factor correction systems.

Results: ✅ Reduced harmonic distortion by 40% ✅ Increased power system reliability ✅ Extended lifespan of critical medical equipment

7. Conclusion

As modern hospitals integrate advanced electronic medical equipment, power quality management becomes increasingly critical. Poor power quality can compromise medical operations, equipment performance, and patient safety. Sunco International Inc. provides hospitals with comprehensive power quality monitoring and mitigation solutions, ensuring safe, reliable, and efficient power distribution.

For inquiries about our hospital power management solutions, please contact Sunco International Inc. today.