In today's energy landscape, businesses across industries like glass manufacturing, refineries, and chemical processing face increasing pressure to optimize their energy consumption, reduce costs, and increase sustainability. One of the most powerful tools available to achieve these goals is process modeling software with mass and energy balancing capabilities, enhanced by advanced features like Computational Fluid Dynamics (CFD).

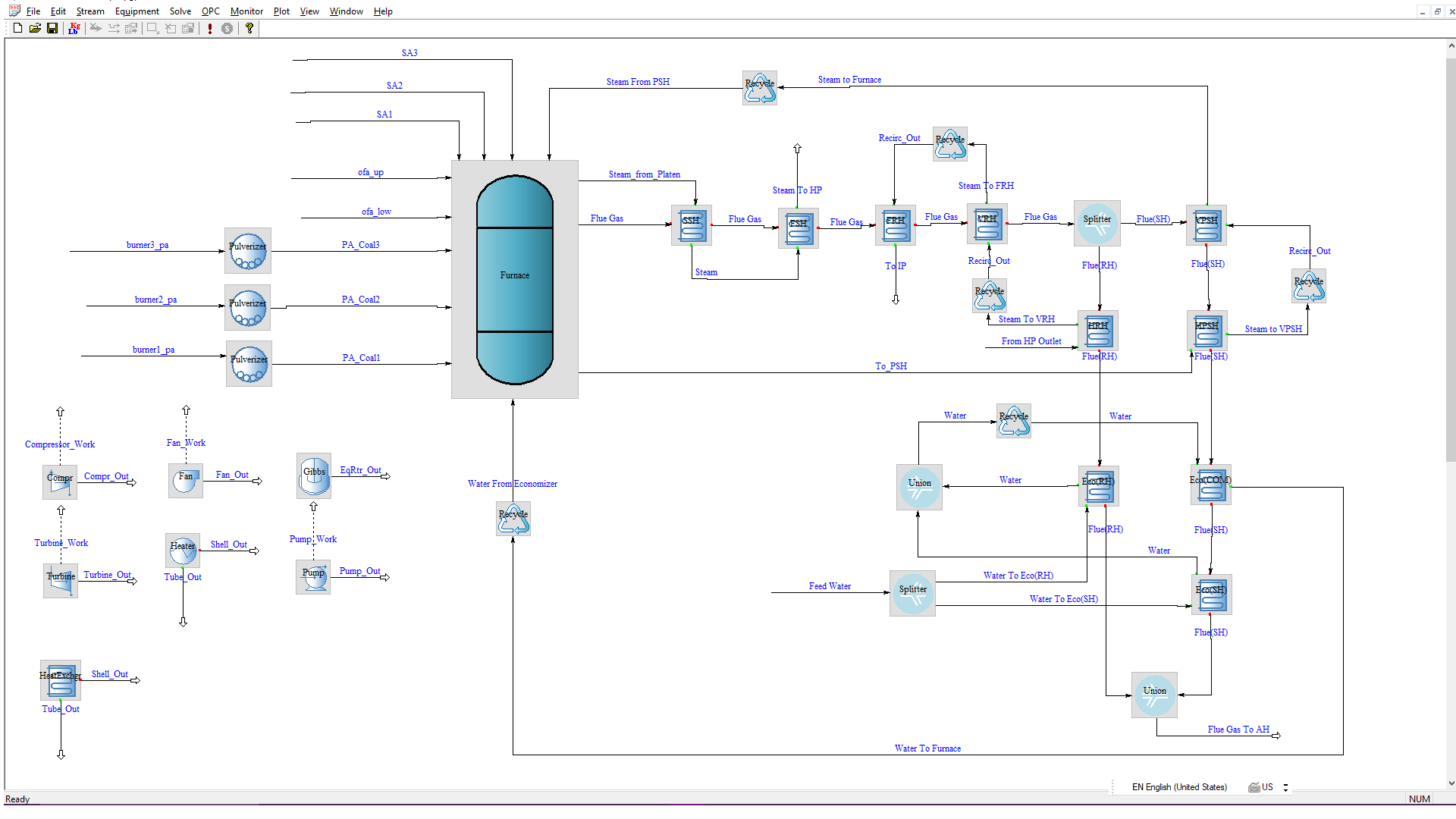

The software interface displayed here demonstrates how this advanced technology can transform the way businesses manage and optimize their energy demands, particularly when integrating with microgrid systems.

The Power of Process Modeling Software for Microgrids

A microgrid is a localized energy system that can operate independently or in conjunction with the main power grid, often incorporating renewable energy sources like solar or wind alongside traditional energy systems. Optimizing the energy demand within a microgrid is critical to ensuring cost efficiency, reliability, and sustainability. This is where process modeling software becomes a game-changer.

Key Benefits for Microgrid Optimization

1. Precise Energy and Mass Balance

The software provides real-time tracking and balancing of energy and material flows within your manufacturing processes, ensuring that the energy supply from the microgrid is used as efficiently as possible. This precision in balancing energy demands allows businesses to prevent waste, lower energy consumption, and seamlessly integrate renewable energy sources.

For industries like glass manufacturing, which rely heavily on consistent energy input, this software ensures that the microgrid provides stable and optimized energy output to maintain production efficiency and product quality.

2. Simulating Various Energy Scenarios

This process modeling software allows you to simulate various energy supply and demand scenarios within your microgrid. For example, manufacturers can simulate energy usage during peak production times or adjust for fluctuations in renewable energy generation from solar or wind. These simulations enable informed decision-making on energy storage and usage, ultimately lowering energy costs and improving grid resilience.

3. Improved Operational Efficiency

The software helps optimize the performance of key energy-intensive equipment, such as boilers, furnaces, and heat exchangers, by modeling their interactions with the microgrid. This results in better thermal management, increased energy efficiency, and longer equipment life. By minimizing inefficiencies, companies can reduce overall energy demand and ensure that their microgrid system operates at peak performance.

For chemical and refinery businesses, this software ensures that the energy supplied by the microgrid is utilized efficiently across various units, such as reactors, distillation columns, and cooling systems, reducing unnecessary energy consumption.

4. Predictive Analytics and Maintenance

Incorporating advanced analytics, the software enables predictive maintenance by monitoring energy flow and equipment performance. It identifies potential issues before they lead to costly breakdowns or energy losses, which is particularly beneficial in industries like refineries, where uptime is critical, and unplanned downtime can be expensive.

5. Seamless Integration of Renewable Energy

Many microgrids are designed to incorporate renewable energy sources such as solar or wind power. This software helps manage the intermittency of renewable energy by optimizing the timing and amount of energy used from battery storage or other energy sources. Businesses can efficiently balance energy use between renewables, grid power, and stored energy, ensuring smooth operations even during fluctuating energy supply.

6. Energy Cost Savings

With optimized energy consumption and improved equipment efficiency, businesses can significantly reduce their energy costs. The software ensures that the microgrid operates at its most cost-effective levels, whether by shifting energy loads, reducing peak demand charges, or maximizing the use of lower-cost renewable energy.

A Game-Changer for Manufacturing Industries

Industries like glass, chemical processing, and refineries are highly energy-intensive, making them ideal candidates for microgrid integration. Process modeling software with mass and energy balancing and CFD capabilities ensures that these industries can optimize their energy use while reducing environmental impact.

The advanced visual interface shown here provides a clear, real-time overview of the energy flows, helping business owners manage their operations with precision. This type of advanced process modeling empowers companies to control every aspect of their energy consumption, from production to sustainability goals, all while staying competitive in a fast-evolving energy landscape.

Conclusion

For manufacturing businesses that consume large amounts of electricity, gas, and water, optimizing energy demand within a microgrid system is not just an option—it’s a necessity. With process modeling software, you can unlock significant energy savings, improve operational efficiency, and make your microgrid system more resilient and sustainable. This cutting-edge solution provides business owners with the tools they need to thrive in a future where energy efficiency and sustainability are paramount.

Make the smart choice for your energy future. Optimize your microgrid energy demand with advanced process modeling today!