In Shuozhou city, Shanxi Province, China, a landmark project spearheaded by Sunco International Inc. has set a new benchmark for environmental responsibility and operational efficiency in the energy sector. The Shentou Power Plant, a significant source of electrical power generation, has recently undergone an extensive combustion retrofit project, a stride towards sustainability that not only showcases Sunco's technical prowess but also underscores China's commitment to reducing its carbon footprint.

Project Overview

The Shentou Power Plant in Shanxi, China, stands as a hallmark of modern engineering and a beacon of environmental progress, thanks to the comprehensive combustion retrofit project led by Sunco International Inc. With a total capacity of 3200 MW, of which 1200 MW is developed in Phase 1 and an additional 2000 MW for phase 2 commissioned in June 2022, the Shentou Power Plant's retrofit project is a significant step forward in the realm of sustainable thermal energy.

The Shentou Power Plant Phase I, operating with two 600MW B&W boilers, faced formidable challenges, including high nitrogen oxide (NOx) emissions and overheating, resulting in a high superheater (SH) spray and lower superheat degree. These issues were not only environmental concerns but also symptomatic of inefficiencies that could affect the plant's longevity and operational costs.

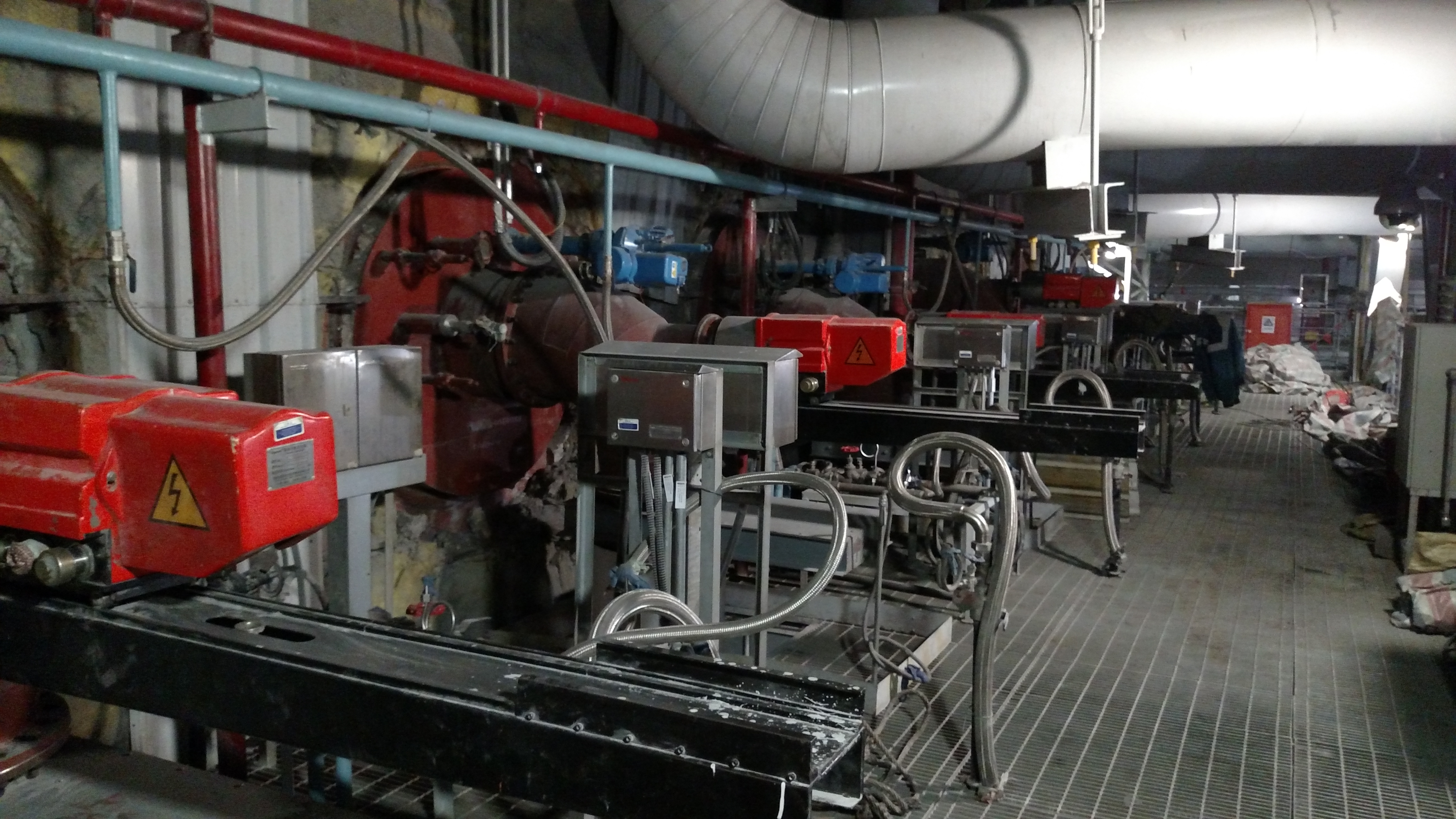

Enter Sunco International Inc., an established leader in power plant retrofitting. Between 2015 and 2017, Sunco embarked on an ambitious project to overhaul Shentou's combustion systems. The project's cornerstone was the integration of Low-NOx Burners (LNB), Over Fire Air (OFA) systems, and an innovative sidewall anti-corrosion system inclusive of plasma burners and small oil burners. The goal was straightforward yet challenging: reduce NOx emissions and enhance the plant's overall performance.

Environmental Impact

Prior to Sunco's intervention, the Shentou Power Plant's NOx emissions hovered between 400-500 mg/Nm3, significantly above the increasingly stringent standards set by global environmental protocols. Post-retrofitting, the plant witnessed a dramatic drop in NOx levels, achieving emissions of less than 280 mg/Nm3. This remarkable reduction not only illustrates Sunco's commitment to green technologies but also represents a significant milestone for China's energy sector in mitigating its impact on the environment.

Technical Advancements

Sunco's approach was multifaceted, involving cutting-edge technology and a deep understanding of combustion dynamics. By installing LNBs, the plant could achieve more complete combustion, reducing the formation of NOx. The OFA system further optimized the combustion process by enabling more precise control of air flow, thus improving efficiency and reducing emissions.

Perhaps most impressively, Sunco introduced a sidewall anti-corrosion system, addressing the vexing problem of boiler corrosion which can lead to unplanned outages and costly repairs. This strategic addition not only prolongs the boiler's lifespan but also ensures that the plant operates under safer conditions.

Operational Benefits

The combustion retrofit project transcended environmental benefits to yield tangible operational improvements. The correction of overheating issues and the reduction of SH spray contributed to a more stable and efficient steam temperature control. The lower superheat degree, a previously noted concern, was also rectified, enhancing the steam cycle efficiency and, consequently, the overall energy output of the plant.

Looking Ahead

The Shentou Power Plant's successful retrofit is a testament to Sunco International Inc.'s expertise and China's broader goals for a cleaner energy future. As the world watches, the project stands as a shining example of what can be achieved with innovation, commitment, and a forward-thinking approach to energy production. The Shentou retrofit project is not just a technical success story; it's a beacon of hope for the future of sustainable power generation.