Revolutionizing the Sugar Industry: How Sugarcane Plants are Turning Biomass into Cost Savings and Clean Energy

Introduction:

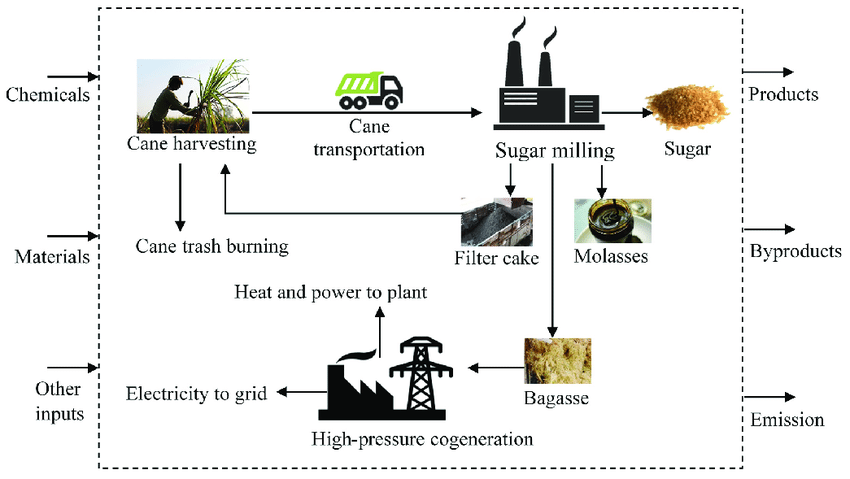

The sugar industry is undergoing a transformative era, pivoting towards a sustainable future. A key player in this revolution is the humble by-product of sugarcane processing: bagasse. This fibrous residue, once considered waste, is now at the forefront of a green energy movement, offering sugarcane plants a golden opportunity to reduce costs and generate clean electricity.

The Power of Bagasse:

Bagasse, derived from sugarcane, is an energy-rich biomass that has been underutilized for years. When processed in modern cogeneration plants, this once-waste material becomes a powerhouse, generating significant amounts of clean electricity. This process not only supplies the energy needs of the sugar mills but also feeds surplus electricity back into the grid, turning sugarcane plants into energy providers.

Cost-Effectiveness and Efficiency:

One of the most compelling aspects of using bagasse for electricity generation is cost-effectiveness. Sugarcane mills traditionally have high energy demands. By using bagasse, which is readily available as a by-product of sugar production, plants can significantly cut down on energy costs. Moreover, the technology for processing bagasse has become more efficient and affordable, making it a viable option even for smaller producers.

Environmental Benefits:

The environmental impact of this shift cannot be overstated. As the world grapples with climate change, renewable energy sources like bagasse present a clean alternative to fossil fuels. Burning bagasse releases far less carbon dioxide compared to conventional energy sources, drastically reducing the carbon footprint of sugarcane plants. This not only aids in global environmental efforts but also enhances the brand image of companies as responsible and sustainable.

Case Studies: Global Leaders in Bagasse Energy:

Companies like Florida Crystals in the United States and Mackay Sugar in Australia are setting the standard in biomass energy. Florida Crystals operates the largest biomass power plant in North America, using bagasse and urban wood waste to produce electricity and steam. Similarly, Mackay Sugar's cogeneration plant significantly contributes to the electricity needs of the Mackay region in Australia. These examples demonstrate the feasibility and success of converting bagasse into a valuable energy resource.

The Future of Sugar Industry:

The use of bagasse for electricity generation is just the beginning. Innovations continue to emerge, enhancing the efficiency and output of these systems. As the technology evolves, so does the potential for sugarcane plants to become even more significant players in the renewable energy sector.

The sugarcane industry is on the cusp of an exciting new era, with bagasse leading the way in sustainable energy production. By embracing this renewable resource, sugarcane plants are not only reducing their operating costs but also contributing to a cleaner, greener planet. This is more than just an operational change; it's a commitment to a sustainable future, showcasing how traditional industries can adapt and thrive in an environmentally-conscious world.

The combined use of boilers and turbines, especially in Combined Heat and Power (CHP) systems, allows for high energy efficiency. CHP systems capture the waste heat from electricity generation for heating purposes, significantly enhancing overall energy utilization.

For many industries, especially those that have access to low-cost fuels or by-product fuels (like biomass from agricultural activities), boilers and turbines offer an economically viable solution for power and heat generation. Industries with their own boilers and turbines can generate their own power and heat, reducing reliance on external power grids and protecting against electricity price fluctuations and grid unreliability. With the advent of environmentally friendly boilers and turbines that can efficiently burn waste or renewable resources, industries can meet environmental regulations and contribute to sustainability goals.