The Pingwei Power Station, located in Pingwei Town, Panji, Huainan, Anhui, China, is a significant coal-fired power station with multiple units, contributing substantially to the region's power generation capacity. The plant currently operates with a total capacity of at least 4540 megawatts (MW). This capacity is distributed across several phases, including Pingwei-I, Pingwei-II, Pingwei-III, and the ongoing construction of Pingwei-IV.

| Unit name | Status | Fuel(s) | Capacity (MW) | Technology | Start year | Retired year |

|---|---|---|---|---|---|---|

| Phase I Unit 1 | operating | coal - bituminous | 630 | subcritical | 1989 | – |

| Phase I Unit 2 | operating | coal - bituminous | 630 | subcritical | 1992 | – |

| Phase II Unit 1 | operating | coal - bituminous | 640 | supercritical | 2007 | – |

| Phase II Unit 2 | operating | coal - bituminous | 640 | supercritical | 2007 | – |

| Phase III Unit 1 | operating | coal - bituminous | 1000 | ultra-supercritical | 2015 | – |

| Phase III Unit 2 | operating | coal - bituminous | 1000 | ultra-supercritical | 2015 | – |

| Phase IV Unit 1 | construction | coal - bituminous | 1000 | ultra-supercritical | – | – |

| Phase IV Unit 2 | construction | coal - bituminous | 1000 | ultra-supercritical | – | – |

The initial phases, Pingwei-I and Pingwei-II, brought online four coal-fired units between 1989 and 2007, collectively contributing 2,540 MW. Pingwei-III, consisting of two additional coal-fired units with a total capacity of 2,000 MW, was approved in 2013, and its construction began shortly thereafter. This phase was successfully commissioned in 2015, with Unit 1 starting operations in June 2015 and Unit 2 in September 2015.

The most recent expansion, Pingwei-IV, adds two more units, each with a capacity of 1,000 MW. These units are still under construction, and their development was recognized as a priority project for Anhui province in 2020, as part of a UHV power hub in the Yangtze River Delta. The expansion was permitted as of November 2022.

This facility, owned and operated by various subsidiaries under the China Power International Development Ltd, exemplifies China's commitment to expanding its power generation capacity while also embracing environmental sustainability practices. The involvement of major contractors like GE Power and Babcock & Wilcox Beijing in supplying critical components such as steam turbines and boilers further underscores the scale and significance of the project.

Sunco-International Inc's Innovative Approach for Unit 3/4 Phase 2 EPC

Sunco-International Inc has introduced advanced low NOx combustion solutions. These are designed to minimize both nitrogen oxides (NOx) emissions and the plant's heat rate, which is a measure of efficiency.

Key Components of the Solution:

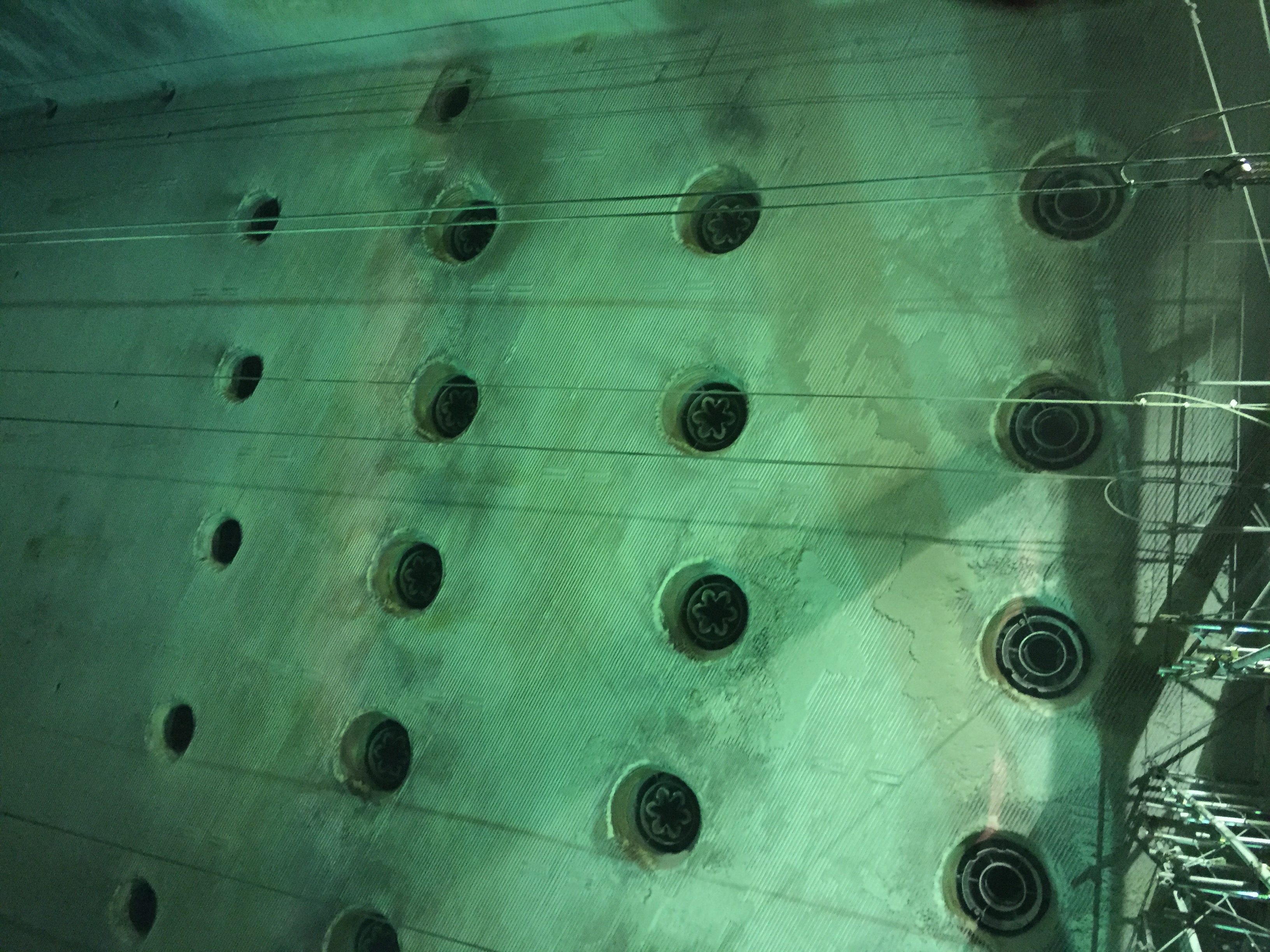

- Advanced Low NOx Burners: These burners are engineered to reduce the formation of NOx during the combustion process. Plasma Low NOx Burners and Low Flow Igniter Burners have been developed and demonstrated at these two units.

- Over-Fire Air (OFA) Systems: OFA systems provide secondary air supply above the combustion zone, enhancing the burnout of unreacted fuel and reducing NOx formation.

- Combustion Optimization Software and Gas Grid: Utilizing an online economizer gas sampling grid, this software enables precise control and optimization of the combustion process.

- Fuel Focus: Targeting medium volatile Chinese bituminous coal, known for its specific combustion characteristics.

Achievements:

- NOx Emissions: Successfully reduced to less than 280 mg/Nm³.

- Heat Rate Minimization: Enhanced plant efficiency by lowering the heat rate.

- Application: This technology has been applied to two 640 MW supercritical boilers in Pingwei.

Enhanced Plant Performance:

- Significant Fuel Cost Savings: By improving efficiency and reducing emissions, plants can operate more economically, particularly in a market with rising fuel costs.

- Improved Plant Operation: Notable improvements include:

- Reduced convective pass metal temperatures, extending the life of the boiler components.

- Decreased sidewall corrosion, reducing maintenance needs and costs.

Meeting Environmental Standards:

- The technology aligns with governmental incentives for low NOx emissions, allowing plants to increase generation while adhering to environmental regulations.

Sunco-International Inc's approach to low NOx combustion represents a significant advancement in the utility industry, particularly in the context of the current competitive landscape. By successfully integrating advanced burners, OFA systems, and optimization software, the company has not only reduced NOx emissions to meet stringent standards but also enhanced overall plant efficiency and operation. This innovation exemplifies how technical ingenuity can address industry challenges, leading to both economic and environmental benefits. Such advancements are crucial in steering the utility sector towards a more sustainable and cost-effective future.