The Essence of CFD in Combustion System Design

CFD modeling has become an indispensable asset in the design and optimization of various boiler types, including wall, corner, and down (arch) fired boilers. Sunco International Inc. leverages two main types of CFD modeling to enhance low NOx components and systems:

-

Air and Flue Gas Flow Modeling:

- This form of modeling ensures balanced airflow within ducts or windboxes. The incorporation of flow correction devices like vanes, perforated plates, or mixers is critical in reducing pressure drops and equalizing flow across ducts and within windboxes.

-

Component Design and Improvement Modeling:

- CFD modeling is also instrumental in the development and enhancement of new low NOx combustion system components, including burners and Over-Fire Air (OFA) ports.

Application of CFD Modeling for Low NOx Systems

Sunco's CFD flow modeling has been utilized in a variety of applications, such as:

- Optimizing secondary air flow in wall-fired boilers.

- Enhancing duct and windbox air flow in T-fired boilers.

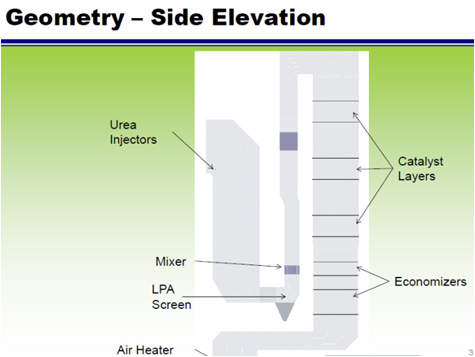

- Refining the design of SCR duct vanes and mixing devices.

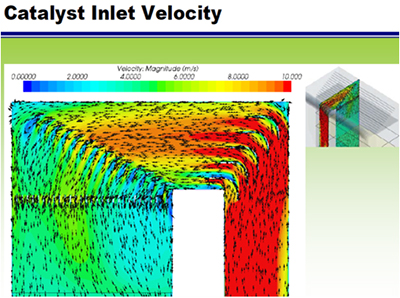

- Simulating the flow field at the inlet of the SCR catalyst reactor.

Furthermore, Sunco's CFD modeling plays a vital role in the design of advanced low NOx combustion components, exemplified by:

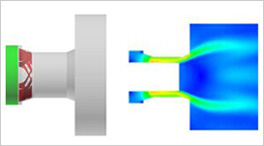

- Velocity models for wall-fired burners.

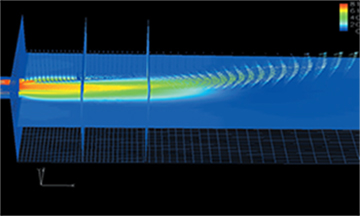

- Penetration models for advanced OFA ports.

The Power of Reaction Kinetics in CFD Modeling

Sunco International Inc. incorporates reaction kinetics within its CFD modeling to simulate combustion reactions in boiler furnaces and denitrification reactions for SNCR and SCR systems. These comprehensive boiler combustion models provide insights into:

- Gaseous emissions.

- Furnace gas temperature and velocity profiles.

- Heat flux within the furnace.

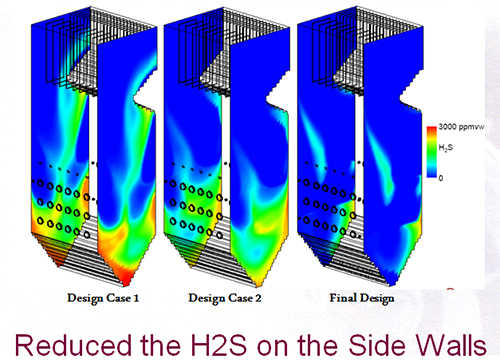

The CFD combustion models are particularly beneficial in optimizing the placement of OFA ports to minimize NOx emissions and prevent conditions that could lead to waterwall corrosion.

Innovations in SNCR and SCR Systems

Sunco International Inc. has pioneered a unique CFD modeling code for SNCR and SCR systems that factors in:

- Reagent droplet evaporation.

- Urea decomposition.

- Denitrification reactions.

This specialized model is critical for determining the optimal location of reagent injectors to achieve maximum NOx reduction with minimal ammonia slip.

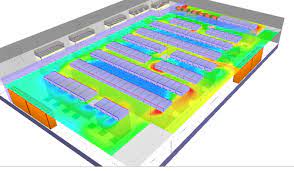

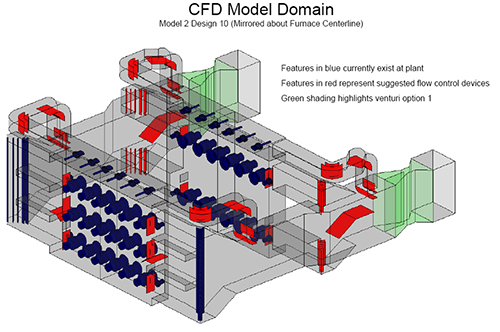

CFD air and flue gas flow modeling are used in order to provide balanced flow within a duct or windbox. These models incorporate flow correction devices such as vanes, perforated plates or mixers to reduce pressure drop and balance flow across ducts and within windboxes. The following some examples of CFD flow modeling applications for low NOx systems.

|

|

| Wall-Fired Boiler Secondary Air Flow Model | T-Fired Boiler Duct and Windbox Air Flow Model |

|

|

| SCR Duct Vanes and Mixing Devices | SCR Catalyst Reactor Inlet Flow Field Simulation |

| CFD modeling is also used for the design and improvement of new components of low NOx combustion systems including burners and OFA ports. The following are examples of CFD models used for developing advanced low NOx combustion components. | |

|

|

| Wall-fired Burner Velocity Model | Advanced OFA Port Penetration Model |

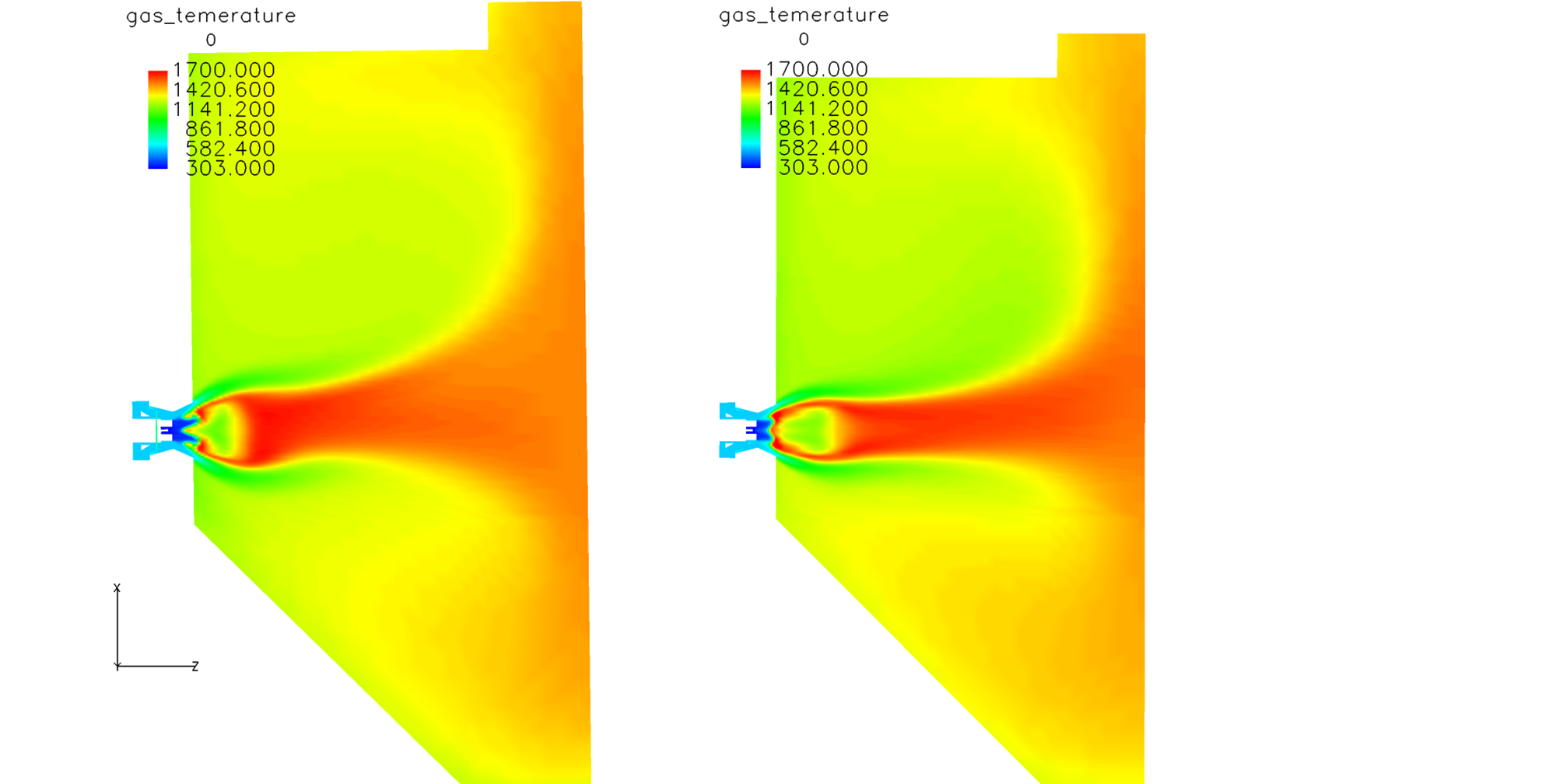

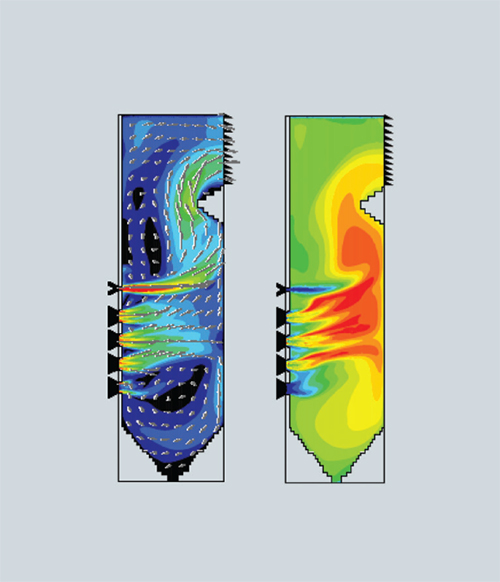

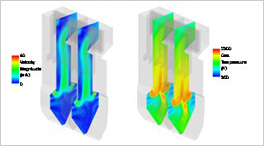

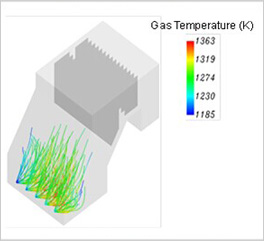

| Sunco International Inc. also utilizes CFD modeling that incorporates reaction kinetics for combustion reaction in boiler furnaces and denitrification reaction for both SNCR and SCR. Boiler combustion models provide many outputs including gaseous emissions, furnace gas, temperature and velocity profiles, and heat flux. Boiler CFD combustion models are used to optimize the location of OFA ports to minimized NOx emissions and reducing conditions that ca lead to waterwall corrosion. The following are a several examples of these models. | |

|

|

| Wall Boiler Velocity and Temperature Profiles | Arch Boiler Velocity and Temperature Profiles |

|

|

| Reduction of H2S on Side Walls | Wall-Fired Boiler CO Profiles |

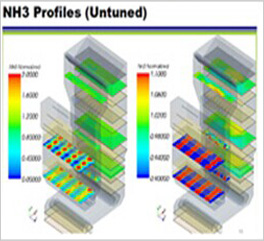

| Sunco International Inc. uses a proprietary CFD modeling code for SNCR and SCR systems that includes reagent droplet evaporation, urea decomposition and denitrification reactions. This model is used to design the proper location of reagent injectors for maximum NOx reduction and minimum ammonia slip. The following are a couple of examples of CFD models for SNCR and SCR. | |

|

|

| SNCR Injector CFD Model | SCR Model Ammonia Profiles |