As power systems grow more dynamic and renewable generation ramps up, one group of assets is proving its continued value: thermal power plants.

But these aren’t yesterday’s coal, gas, or biomass units.

Today’s thermal plants are transforming—from static baseload generators into flexible, intelligent, efficiency-driven power hubs. And whether you’re running a 600MW coal unit, a fast-start GT, or a solar + battery + steam hybrid plant, one thing is clear:

To compete in the modern grid, you need more than just megawatts.

You need a platform that helps your plant think.

The Thermal Upgrade: Three Essential Transformations

No matter the fuel or configuration, the most forward-looking plants are investing in:

- Faster ramping and dispatch flexibility

- Operational and energy efficiency

- Smarter, data-driven operations

Let’s break it down.

1. Regulate Faster, Respond Smarter

Modern grids demand rapid cycling, deep turndown, and fast ramping. Plants must adapt or be left behind.

Key challenges include:

- Maintaining combustion stability at low load

- Ramping up without stress on critical components

- Providing frequency support and spinning reserve on demand

AI-powered assistants now enable:

- 30% reduction in startup and shutdown time

- 50% improvement in ramp rate agility

- Smarter control logic to reduce wear and boost performance

This applies not only to coal-fired plants but also to combined cycle gas turbines, CHP systems, biomass boilers, and even WTE facilities.

2. Run Leaner, Optimize Continuously

Efficiency is no longer a back-end metric—it’s now a frontline strategy.

Forward-thinking operators are embracing:

- Real-time heat rate diagnostics

- Adaptive combustion optimization

- Load-following logic that maintains best-in-class efficiency curves

- Proactive O&M scheduling based on performance drift

The result?

More output with less fuel.

More stability with fewer interventions.

And more profitability, even during partial-load or ramping conditions.

One plant recently used this approach to reduce coal consumption by 0.8g/kWh across an entire quarter.

3. Operate With Intelligence, Not Just Experience

Knowledge loss from retirements. SOPs buried in PDFs. Fault logs siloed in legacy systems. Sound familiar?

It doesn’t have to be that way.

Today’s most powerful upgrade is an industrial AI assistant that connects:

- SOPs and OEM manuals

- DCS control logic

- Historical events and trips

- Shift logs, fault trees, and real-time data

Operators can now ask:

“How do I restart after a load rejection trip?”

“What’s the best combustion curve for high-ash fuel?”

“Show me historical trip causes for Turbine B.”

And receive an explainable answer—with diagrams, data, and source documents.

Result:

- Less guesswork

- Faster response

- Safer operation

The Business Case: Real Dollars, Real Impact

|

Use Case |

Annual Value (per unit) |

|

Reduced downtime (20 hours/year) |

~$300,000 |

|

Optimized fuel use (0.5–1% savings) |

$150,000–$300,000 |

|

Improved ramping/ancillary service |

$100,000+ |

|

O&M cost reduction + training savings |

$70,000+ |

For multi-unit fleets, the gains multiply quickly.

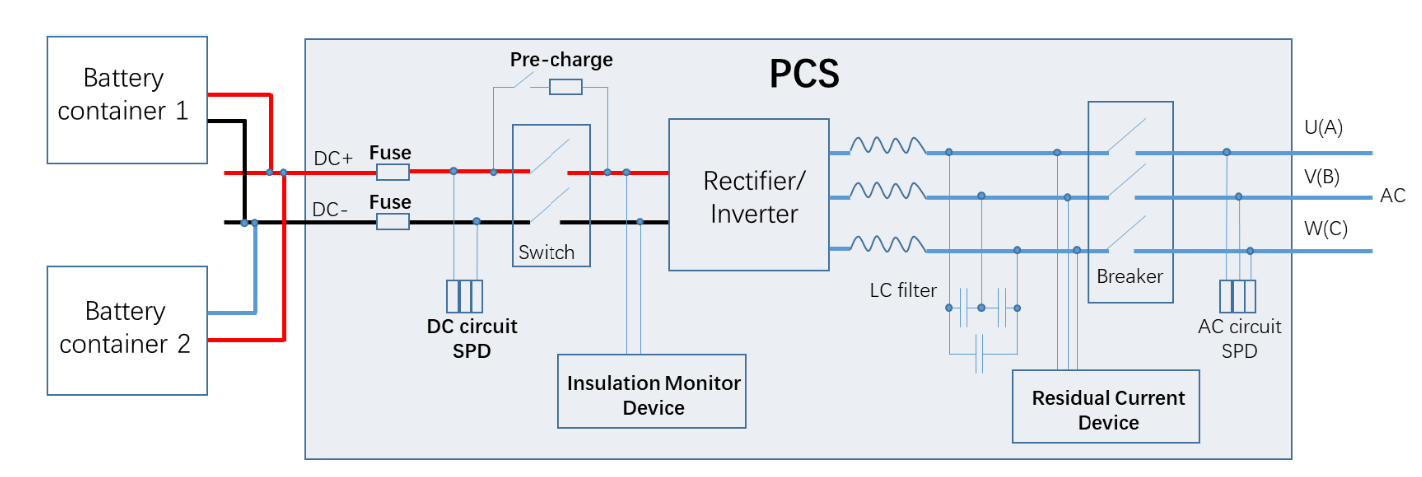

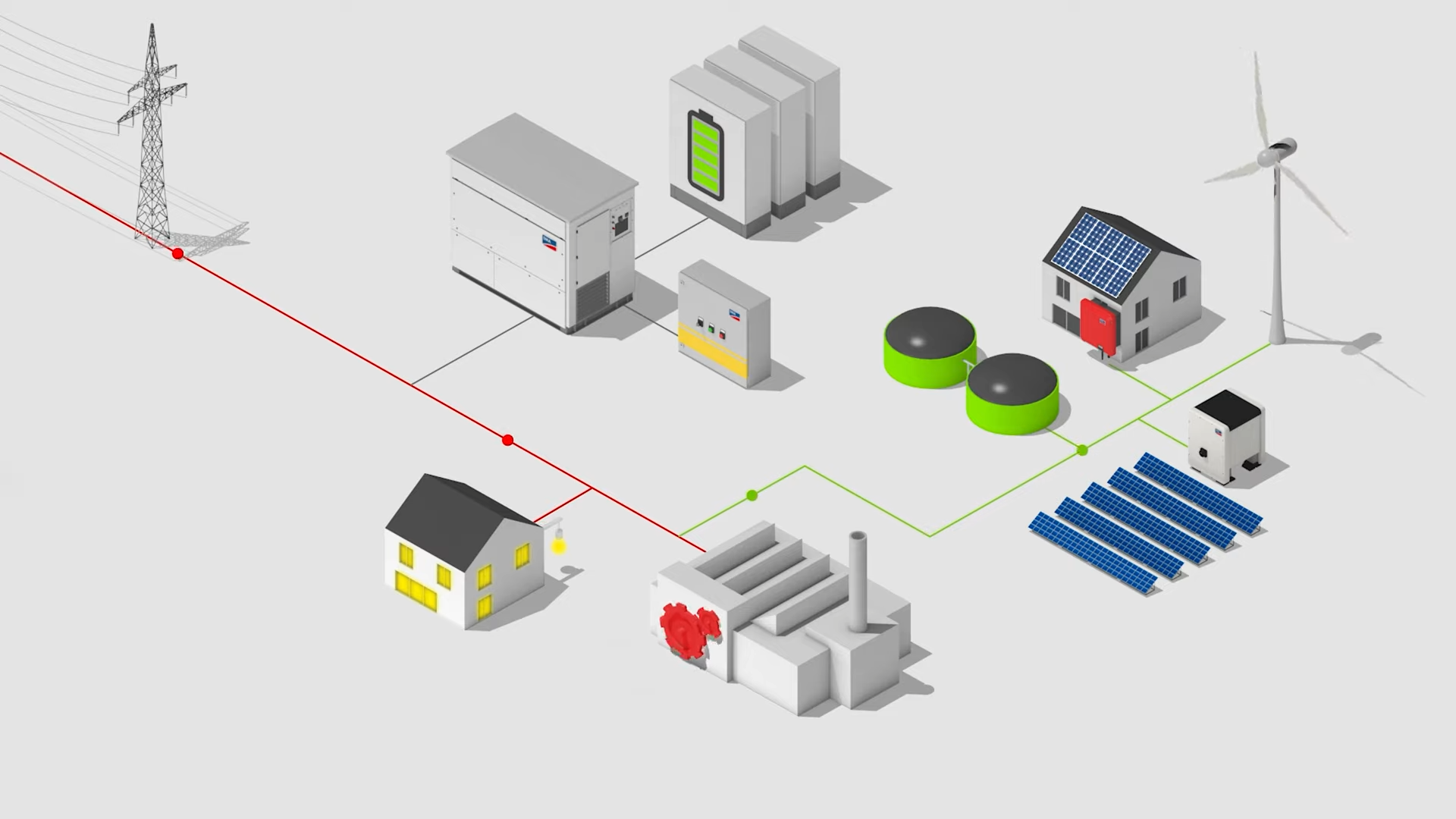

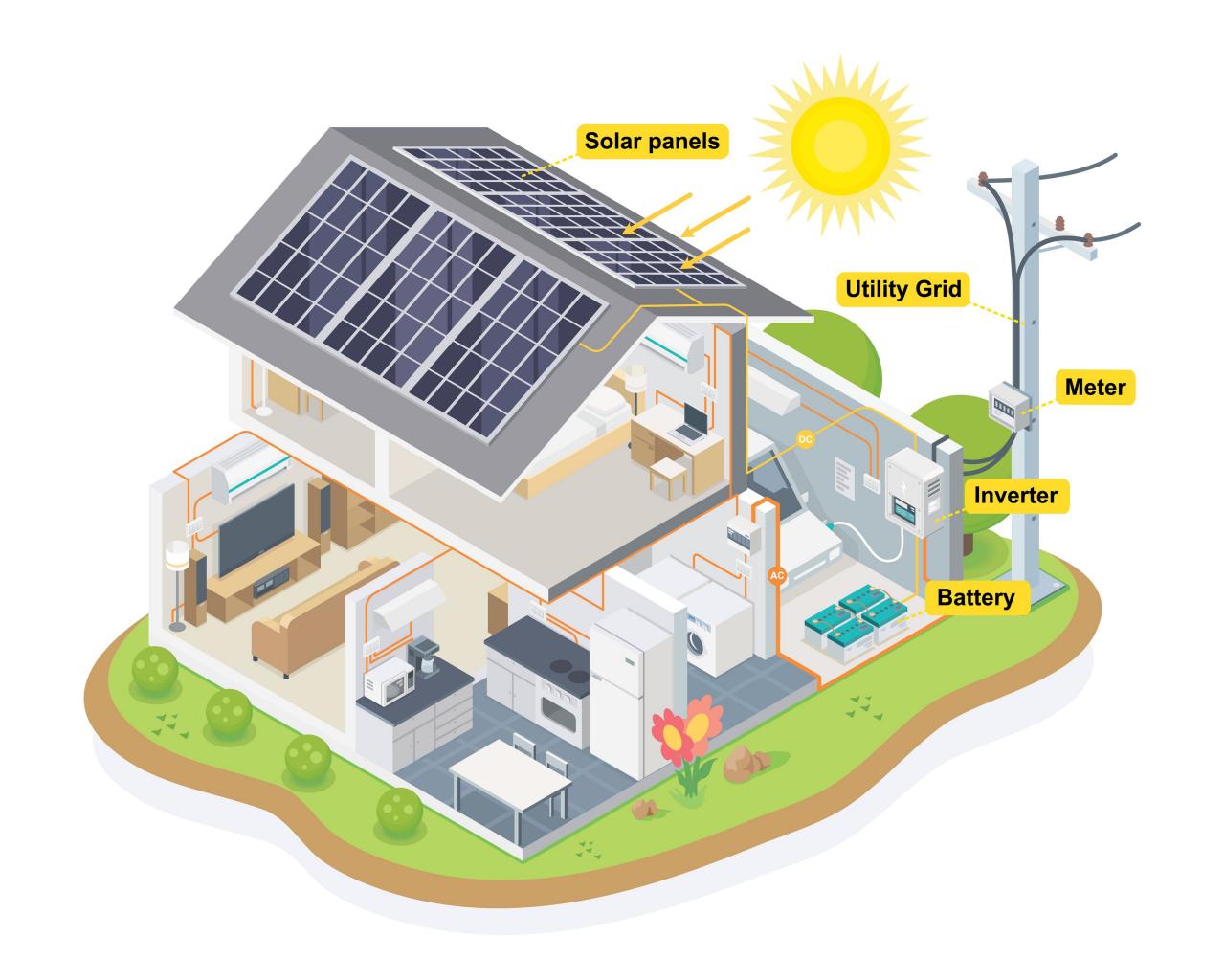

Bonus: Solar + Battery + Thermal—An Intelligent Hybrid

Hybrid plants aren’t just about resource diversity.

They’re about coordinated, intelligent dispatch across PV, BESS, and thermal.

With AI optimizing:

- Battery charge/discharge strategy

- Thermal spinning reserve levels

- Real-time market response and efficiency curves

Your plant doesn’t just follow the load.

It leads the dispatch strategy.

Final Thought: Upgrade Your Megawatts With a Brain

The modern plant isn’t defined by what it burns.

It’s defined by how well it responds, adapts, and performs.

Whether you operate coal, gas, biomass, or hybrid systems, the future belongs to facilities that are:

✅ Fast

✅ Efficient

✅ Intelligent

It’s time to give your plant a brain—and unlock its full potential.