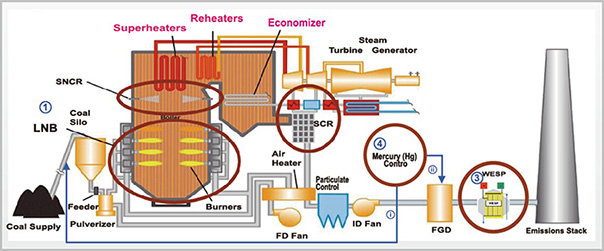

Sunco International Inc's energy technology applications include intelligent combustion optimization software: expert system, neural network systems and optimization algorithms combined into a program that runs under a Windows operating system. Boiler combustion optimization is used to identify combinations of control settings that achieve optimum heat rate, minimum NOx emissions or other important goals of plant operation.

What intelligent combustion optimization software can do?

This AI Software is used to guide the plant engineer through a series of parametric boiler tests which gather a database to characterize boiler operations over a wide range of conditions. The software then analyzes the data and identifies optimal boiler operating conditions. The recommended control settings are typically used to obtain the desired NOx levels while achieving the lowest possible unit heat rate.

Optimization process:

• Preliminary test for calibration of instruments, equipment maintenance and make the necessary adjustments

• Pulverized coal combustion system is adjusted to reduce air an coal imbalances and improve mill performance

• Installation of new, advanced diagnostic instruments as required, providing key data for improved combustion optimization: Furnace Gas Exit Temperature (FEGT) probes, online fly ash LOI analyzers, and furnace camera thermography technology. Data from these advanced diagnostic tools can be incorporated into the optimization software and used in determining optimal boiler settings

• Parametric tests are conducted using the optimization software to determine the optimal boiler control settings. These tests are carried out over the load range and provided the data needed to specify key parameters such as overfire air damper setting, economizer O2 level, burner air damper settings and burner tilt angle as functions of load.

• Analysis of test data and modeling to incorporate algorithms into the optimization software

• Development of software user interfaces with the boiler model integrated into the software. The control system is then configured by an on-site installation software consultant

to permit automatic operation at these optimized settings.

• Conduct on-site verification testing of the software by varying boiler control settings.

• Training of operating personnel for typical optimization objectives:

• Optimum heat rate

• Minimum NOx emissions

• Minimum mercury emissions

• Reduced furnace slagging and convection fouling

• Reduced unburned carbon in fly ash

• Steam temperature near design value