As power systems grow more dynamic and renewable generation ramps up, one group of assets is proving its continued value: thermal power plants.

But these aren’t yesterday’s coal, gas, or biomass units.

Today’s thermal plants are transforming—from static baseload generators into flexible, intelligent, efficiency-driven power hubs. And whether you’re running a 600MW coal unit, a fast-start GT, or a solar + battery + steam hybrid plant, one thing is clear:

To compete in the modern grid, you need more than just megawatts.

You need a platform that helps your plant think.

The Thermal Upgrade: Three Essential Transformations

No matter the fuel or configuration, the most forward-looking plants are investing in:

- Faster ramping and dispatch flexibility

- Operational and energy efficiency

- Smarter, data-driven operations

Let’s break it down.

1. Regulate Faster, Respond Smarter

Modern grids demand rapid cycling, deep turndown, and fast ramping. Plants must adapt or be left behind.

Key challenges include:

- Maintaining combustion stability at low load

- Ramping up without stress on critical components

- Providing frequency support and spinning reserve on demand

AI-powered assistants now enable:

- 30% reduction in startup and shutdown time

- 50% improvement in ramp rate agility

- Smarter control logic to reduce wear and boost performance

This applies not only to coal-fired plants but also to combined cycle gas turbines, CHP systems, biomass boilers, and even WTE facilities.

2. Run Leaner, Optimize Continuously

Efficiency is no longer a back-end metric—it’s now a frontline strategy.

Forward-thinking operators are embracing:

- Real-time heat rate diagnostics

- Adaptive combustion optimization

- Load-following logic that maintains best-in-class efficiency curves

- Proactive O&M scheduling based on performance drift

The result?

More output with less fuel.

More stability with fewer interventions.

And more profitability, even during partial-load or ramping conditions.

One plant recently used this approach to reduce coal consumption by 0.8g/kWh across an entire quarter.

3. Operate With Intelligence, Not Just Experience

Knowledge loss from retirements. SOPs buried in PDFs. Fault logs siloed in legacy systems. Sound familiar?

It doesn’t have to be that way.

Today’s most powerful upgrade is an industrial AI assistant that connects:

- SOPs and OEM manuals

- DCS control logic

- Historical events and trips

- Shift logs, fault trees, and real-time data

Operators can now ask:

“How do I restart after a load rejection trip?”

“What’s the best combustion curve for high-ash fuel?”

“Show me historical trip causes for Turbine B.”

And receive an explainable answer—with diagrams, data, and source documents.

Result:

- Less guesswork

- Faster response

- Safer operation

The Business Case: Real Dollars, Real Impact

|

Use Case |

Annual Value (per unit) |

|

Reduced downtime (20 hours/year) |

~$300,000 |

|

Optimized fuel use (0.5–1% savings) |

$150,000–$300,000 |

|

Improved ramping/ancillary service |

$100,000+ |

|

O&M cost reduction + training savings |

$70,000+ |

For multi-unit fleets, the gains multiply quickly.

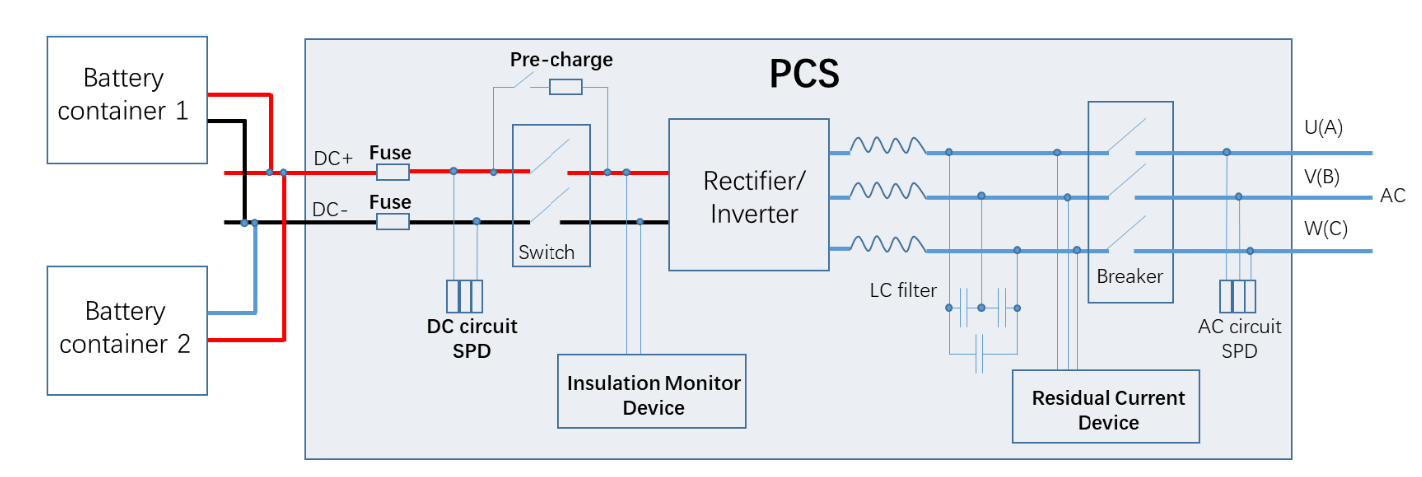

Bonus: Solar + Battery + Thermal—An Intelligent Hybrid

Hybrid plants aren’t just about resource diversity.

They’re about coordinated, intelligent dispatch across PV, BESS, and thermal.

With AI optimizing:

- Battery charge/discharge strategy

- Thermal spinning reserve levels

- Real-time market response and efficiency curves

Your plant doesn’t just follow the load.

It leads the dispatch strategy.

Final Thought: Upgrade Your Megawatts With a Brain

The modern plant isn’t defined by what it burns.

It’s defined by how well it responds, adapts, and performs.

Whether you operate coal, gas, biomass, or hybrid systems, the future belongs to facilities that are:

✅ Fast

✅ Efficient

✅ Intelligent

It’s time to give your plant a brain—and unlock its full potential.

The development and expansion of the healthcare industry are heavily reliant on a stable and high-quality power supply. A hospital's power distribution system is a crucial factor in ensuring reliable operations. With advancements in modern technology, hospital power infrastructure has improved significantly. However, as hospitals integrate more electronic medical equipment, they introduce a common challenge: the generation of harmonic distortions that degrade power quality. Medical devices require high-quality power to function correctly, and harmonic distortions can lead to voltage and current waveform distortions, impacting overall power quality. If not properly managed, these distortions can cause operational failures, reduce equipment lifespan, and interfere with critical medical procedures. Addressing power quality issues is essential for hospital administrators and design teams.

Keywords: Hospital Power Distribution System; Medical Equipment; Power Quality; Harmonic Distortion and Mitigation; System Solutions

1. Introduction

The advancement of hospitals and medical facilities requires sophisticated technology to ensure reliable power infrastructure. Hospitals must achieve efficient and stable energy use to reduce operational costs and enhance service quality. Hospital power distribution systems serve as the backbone of medical operations, consisting of various nonlinear and time-variant electrical and medical devices. These devices generate harmonic distortions, which, if left unmitigated, can disrupt essential operations and even compromise patient safety. Conducting thorough analyses and implementing solutions for power quality management in hospitals is critical.

2. Sources and Characteristics of Harmonic Distortions in Hospital Power Systems

Hospital power distribution systems have multiple sources of harmonic distortions, which can be categorized into three main groups: medical equipment, information and communication systems, and electrical appliances.

Medical Equipment

Hospitals rely on a wide range of medical devices, many of which contain power electronics that generate harmonic distortions. Examples include:

- CT Scanners: These devices use high-frequency, high-voltage generators, converting three-phase AC power into high-frequency DC and then back to AC. This process introduces significant harmonic currents, with total harmonic distortion (THD) reaching up to 30%.

- Magnetic Resonance Imaging (MRI) Systems: MRI machines use alternating magnetic fields and radiofrequency pulses, creating harmonic distortions with a THD of around 20%.

- Linear Accelerators (LINACs): These devices, used for radiation therapy, operate with high-frequency power supplies and pulse modulation systems, leading to harmonic distortions reaching 40–50%.

- X-ray Machines: These devices are transient loads with instantaneous power spikes exceeding 60–70 kW. Their rectifier circuits contribute to harmonic distortion levels between 30% and 50%.

Information and Communication Systems

Hospitals increasingly depend on digital systems for medical records, imaging, telemedicine, and real-time patient monitoring. These systems involve thousands of computers and network devices that contribute to harmonic pollution.

- Uninterruptible Power Supply (UPS) Systems: UPS systems are essential for hospitals to maintain power during outages. However, UPS devices using IGBT and PWM technologies generate substantial harmonic currents. A three-phase, six-pulse rectifier UPS system can introduce THD levels between 30% and 40%.

- Network and Telecommunication Devices: Data centers, audio/video communication systems, and telemedicine services operate continuously, generating harmonic distortions.

Electrical Equipment

- Lighting Systems: Fluorescent lighting and LED fixtures generate significant third-order harmonic currents. When connected in three-phase systems, these harmonics accumulate in the neutral wire, increasing the risk of overheating.

- HVAC Systems and Variable Frequency Drives (VFDs): Many hospitals use VFDs for HVAC systems and ventilation. These drives generate substantial 5th and 7th-order harmonic distortions, reducing overall power quality.

3. Impact of Harmonic Distortions on Hospital Power Systems

Impact on Power Networks

Harmonics increase system losses, cause overheating, and can trigger unintended protective device operations. Harmonic resonance can occur when reactive power compensation capacitors match the system’s impedance, amplifying harmonic levels beyond safe thresholds.

Impact on Transformers

Harmonics increase core and copper losses in transformers, reduce efficiency, and lead to excessive heating, which may reduce the transformer’s lifespan.

Impact on Motors and Generators

Harmonic distortions lead to additional motor losses, mechanical vibrations, noise, and harmonic-induced overvoltage, reducing operational efficiency.

Impact on Medical Equipment

Sensitive diagnostic and therapeutic devices can experience erratic behavior, measurement inaccuracies, and unexpected shutdowns due to voltage distortions caused by harmonics.

Impact on Communication Systems

Harmonic distortions induce electromagnetic interference (EMI), degrading the performance of network infrastructure, telemedicine services, and real-time monitoring systems.

4. Power Quality Monitoring and Mitigation Requirements

Power Quality Requirements for Hospitals

Hospitals require high power quality for reliable medical equipment operation. The key characteristics include:

- Stable Voltage and Frequency

- Minimal Harmonic Distortions

- Continuous Power Supply (No Interruptions)

Proposed Power Quality Solutions

- Centralized and Localized Harmonic Filtering: Active and passive harmonic filters should be installed at the main distribution level and at individual loads.

- UPS and Voltage Regulation Systems: Properly rated UPS systems with power factor correction help mitigate harmonic distortions.

- Isolation Transformers: These transformers help reduce the impact of harmonics on sensitive medical equipment.

- Smart Power Monitoring Systems: Real-time monitoring enables hospitals to detect power quality issues before they cause failures.

5. Hospital Power Quality Monitoring and Mitigation Solutions by Sunco International Inc.

Solution Overview

Sunco International Inc. offers comprehensive power quality monitoring and mitigation solutions designed to enhance the reliability of hospital power distribution networks. Our solutions include:

- Real-time power quality monitoring

- Harmonic filtering systems

- Voltage stabilization solutions

- Predictive maintenance using AI-powered analytics

Features of Our Power Quality Management System

✅ Real-time Monitoring – Live tracking of voltage, current, harmonics, and power factor ✅ Automated Alerts & Reporting – Instant notifications for abnormal power quality events ✅ Harmonic Mitigation – Active and passive filters to ensure compliance with IEEE 519 standards ✅ Cloud-Based Analytics – Remote monitoring and predictive maintenance ✅ Energy Efficiency Optimization – Identifies power waste and optimizes hospital power usage

6. Case Study: Power Quality Improvement in a Large Hospital

Background: A major metropolitan hospital experienced frequent disruptions due to voltage fluctuations and harmonic distortions.

Solution:

- Installed harmonic filters to mitigate 3rd, 5th, and 7th order harmonics.

- Deployed real-time power monitoring with predictive analytics.

- Optimized power factor correction systems.

Results: ✅ Reduced harmonic distortion by 40% ✅ Increased power system reliability ✅ Extended lifespan of critical medical equipment

7. Conclusion

As modern hospitals integrate advanced electronic medical equipment, power quality management becomes increasingly critical. Poor power quality can compromise medical operations, equipment performance, and patient safety. Sunco International Inc. provides hospitals with comprehensive power quality monitoring and mitigation solutions, ensuring safe, reliable, and efficient power distribution.

For inquiries about our hospital power management solutions, please contact Sunco International Inc. today.

In today's industrial landscape, power generation, chemical production, and heavy manufacturing enterprises face a new kind of operational challenge—not from equipment failure, but from information overload and knowledge fragmentation.

Shift operators struggle to find reliable procedures. Engineers waste time piecing together fault histories. Safety teams drown in disconnected compliance documents. And perhaps most critically, decades of hands-on knowledge risk disappearing as senior experts retire.

It’s time for a smarter solution.

Introducing the Industrial Intelligent Knowledge Platform

Imagine being able to ask,

1 “What caused Pump B to trip last week?”

2 “What’s the emergency response if coolant pressure drops below spec in Unit 4?”

3 “Show me the standard operating procedure for hydrogen seal replacement.”

Now imagine receiving answers not from a search bar…

…but from a purpose-built AI that understands your plant, your procedures, and your people.

Welcome to the Industrial Intelligent Knowledge Platform — a ChatGPT-style assistant customized for the most complex industrial operations on Earth.

What Makes It Different?

Unlike generic AI chatbots, this system is:

- Built for Industry: It draws from technical manuals, DCS logic, equipment diagrams, maintenance logs, and regulatory files.

- Backed by Knowledge Graphs: Every answer is explainable, traceable, and structured.

- Engineered for Trust: Users can click to see source documents, revision dates, and original authors.

Whether you're a control room operator, a shift supervisor, or a safety officer — answers are just a question away.

Real-World Benefits & ROI

Each plant runs on unique data, systems, and standard operating procedures. Every employee needs access to that tribal knowledge — fast. This platform delivers just that, resulting in:

Direct Cost Savings

- Reduce downtime by enabling faster diagnostics and recovery:

Even saving 1 hour per fault at $100,000/hr leads to $1M+ annual savings. - Avoid redundant inspections or repairs by surfacing historical work orders.

- Slash training costs by replacing long onboarding cycles with conversational coaching.

Operational Efficiency Gains

- Faster decision-making in shift handovers, emergency conditions, or compliance checks.

- More productive crews who can query diagrams, control logic, or alarms in real time.

- Fewer errors and missed steps through contextual guidance and process memory.

Improved Safety and Reliability

- Quicker hazard response by querying past incident response actions.

- Consistent compliance with EHS protocols and permit-to-work requirements.

- Institutional knowledge retention as senior staff retire or transition.

This platform turns scattered knowledge into an organized, intelligent, and accessible asset — leading to millions in avoided losses and gains in reliability.

Inside the Platform

The architecture combines:

- Large Language Models (LLMs) trained on real industrial documentation

- Knowledge Graphs built from SOPs, work orders, and equipment hierarchies

- Visual Interfaces with support for PDFs, CADs, alarms, diagrams, and voice

It integrates seamlessly with your existing SCADA, EAM, DMS, or LMS systems, and can be deployed either on-prem or in a hybrid edge/cloud setup.

Use Cases from the Field

Boiler Room Assistant

Ask about system parameters, trip sequences, or fault causes for 600MW units.

⚗️ Chemical Plant Maintenance

Field technicians scan a QR code and pull up historical fixes, disassembly videos, or EAM records.

EHS Compliance Trainer

Auto-generate quizzes from plant rules and verify team readiness before inspections.

Battery Storage Monitoring

BMS alarms decoded instantly with response actions and vendor-specific logic.

☢️ Nuclear Knowledge Hub

Connect emergency flowcharts, NNSA specs, and real-time procedures — all with audit-grade traceability.

Commercial Strategy

The platform offers:

- ✅ SaaS subscriptions for medium-scale operations

- ✅ On-prem enterprise deployments with SLA support

- ✅ Add-on modules: Maintenance, Training, Compliance

Target customers include power plants, chemical complexes, energy storage sites, and ESG-driven enterprises.

Market Impact & Revenue Forecast

With potential customer savings exceeding $1–5M annually per site through reduced downtime, better compliance, and fewer accidents, the return on investment is undeniable.

Ready to Transform Your Plant?

The Industrial Intelligent Knowledge Platform isn’t just about technology. It’s about empowering people, preserving institutional wisdom, and enabling safer, smarter, and faster decision-making.

Because the future of industry won’t be built on documents.

It will be built on knowledge that talks back.

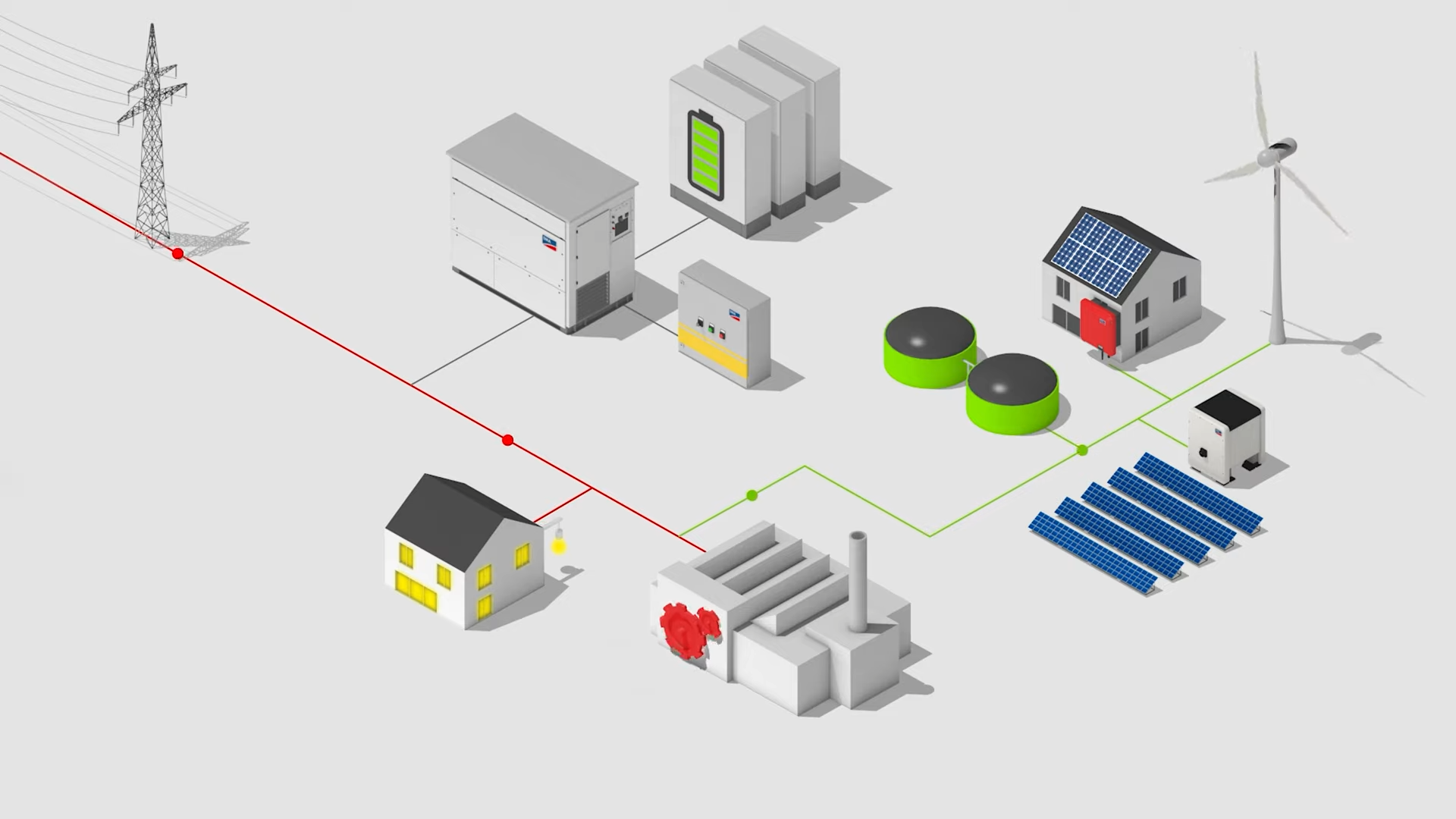

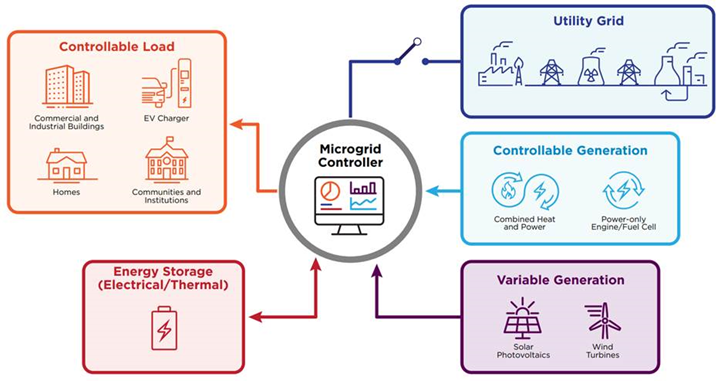

In today’s fast-paced, energy-dependent world, industries such as chemical plants, refineries, glass manufacturing, and other heavy manufacturers are facing the challenge of balancing increasing energy costs with the demand for reliability, sustainability, and operational flexibility. Microgrids with battery storage are emerging as a transformative solution, offering a robust way to optimize energy consumption, reduce operational costs, and enhance energy security. Furthermore, by offering grid service capabilities, these microgrids can provide additional financial benefits and contribute to overall grid stability.

Why Microgrids with Battery Storage Matter

Industries like chemicals, refineries, glass manufacturing, and other heavy manufacturing sectors are known for their high energy consumption, requiring vast amounts of electricity, gas, and water to maintain their operations. A microgrid combined with battery storage offers these energy-intensive businesses significant advantages:

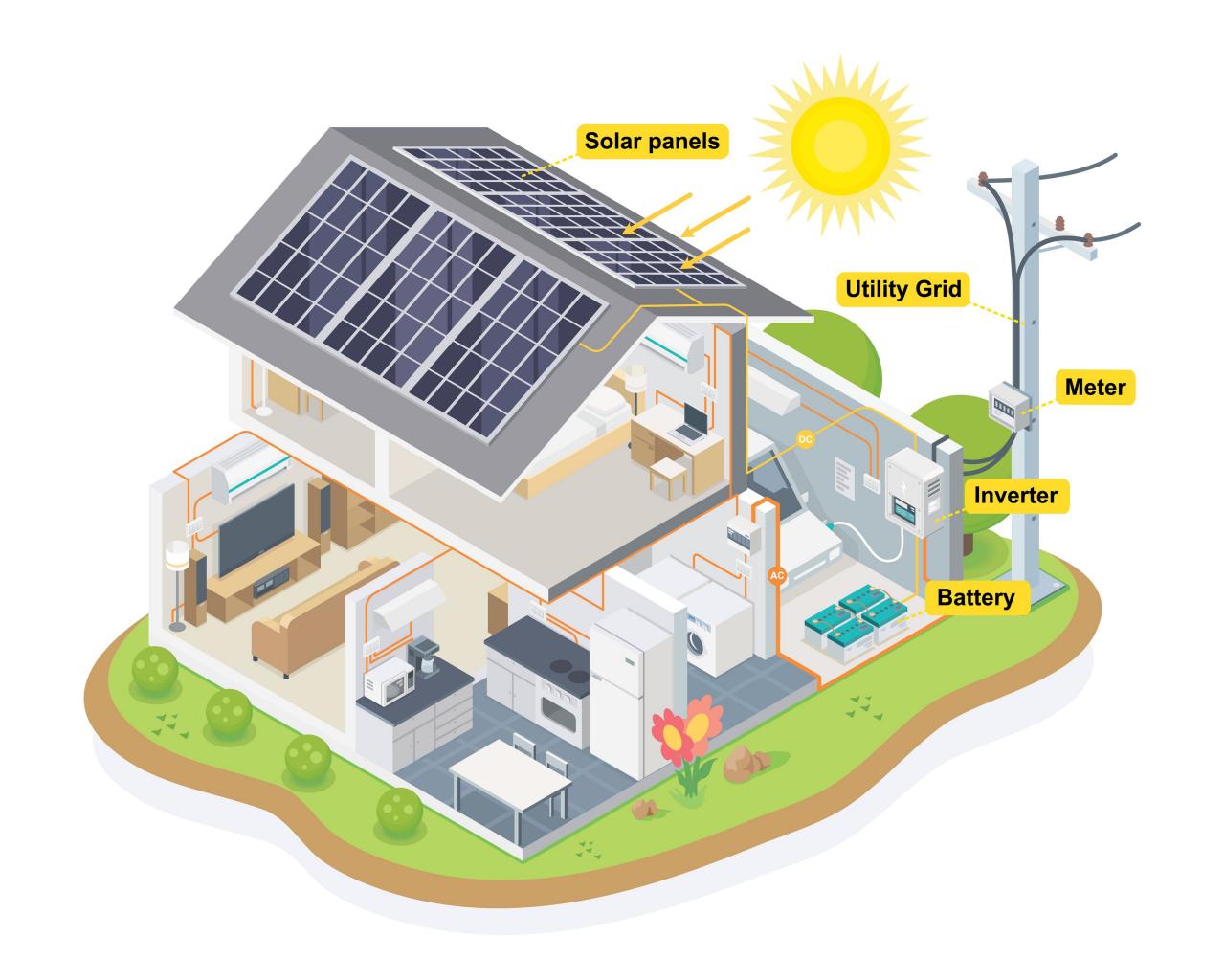

1. Energy Cost Savings through Load Management

With microgrids, businesses can generate their own energy—often via solar or wind—while battery storage systems allow them to store excess power generated during low-demand periods. This stored energy can then be used during peak times when electricity rates are highest, offering significant cost savings. Peak shaving strategies enable companies to avoid the steep costs associated with peak demand charges, leading to more predictable and lower energy bills.

In industries such as glass manufacturing, where energy costs can account for a large portion of operational expenses due to high-temperature furnaces, a microgrid with battery storage ensures that energy consumption remains efficient while keeping costs under control.

2. Improved Energy Reliability and Resilience

Chemical plants, refineries, and glass manufacturing facilities cannot afford downtime. A microgrid enhances energy reliability by allowing these businesses to disconnect from the traditional power grid during outages, blackouts, or other disruptions. Batteries within the microgrid ensure that critical operations continue running smoothly, improving the resilience of the entire facility. Control systems and advanced diagnostics can help maximize system uptime, ensuring continuity even during grid disturbances.

For glass manufacturers, where continuous heat is required in furnaces to avoid material defects, microgrids provide an invaluable safeguard against unexpected power interruptions, minimizing the risk of product loss.

3. Enhanced Sustainability and Regulatory Compliance

Microgrids with battery storage help businesses meet sustainability goals by enabling a higher penetration of renewable energy, such as solar or wind. In industries where carbon emissions and environmental impact are under scrutiny, integrating battery storage allows for a more significant use of renewable energy sources, helping to meet regulatory requirements and corporate sustainability targets. This not only improves the business's environmental footprint but also enhances its market reputation.

Glass manufacturers, in particular, can use renewable energy integrated into a microgrid to power energy-intensive melting processes, thereby reducing their reliance on traditional, carbon-heavy energy sources and aligning with sustainability initiatives.

4. Grid Independence and Energy Autonomy

The global energy landscape is rapidly shifting, and the cost of grid electricity can be unpredictable. A microgrid with battery storage provides businesses with energy autonomy, enabling them to generate, store, and control their energy independently from the grid. This is especially beneficial for industries in remote locations or regions prone to power outages. Advanced energy management systems allow for seamless integration and dispatch of stored energy across assets or entire fleets, ensuring businesses can dynamically respond to changing energy needs.

For refineries and chemical plants operating in isolated regions or where grid infrastructure may be unstable, microgrids can ensure the stability of production processes without reliance on external energy sources.

5. Operational Flexibility and Scalability

As businesses grow, their energy needs change. A microgrid with battery storage is highly scalable, allowing companies to add or remove energy assets as required. This ensures that the system remains flexible and aligned with evolving business needs, without the need for significant upfront infrastructure changes. Technology-agnostic systems that integrate various types of batteries and inverters provide businesses with complete flexibility over their energy choices.

For glass manufacturers looking to scale their operations or add new production lines, microgrids allow for seamless expansion of energy capacity without major overhauls.

Unlocking Additional Value: Grid Service Capabilities for All Industries

Beyond optimizing internal energy consumption, microgrids with battery storage offer additional value by participating in grid services that contribute to broader energy market functions, helping stabilize the main grid while generating new revenue streams for businesses. Any industry using a microgrid, whether it's manufacturing, chemicals, refineries, or commercial sectors, can benefit from these services.

6. Providing Grid Services

Microgrids can support the main grid by offering demand response, frequency regulation, and capacity services. For instance, during times of high grid demand, your facility can reduce its energy draw or even export excess power stored in the batteries back to the grid, contributing to grid stability and earning revenue through programs like demand response or capacity market participation.

For a chemical plant, refinery, or glass manufacturer, where energy demand is variable, the ability to participate in grid service markets can create an additional revenue stream while supporting regional grid reliability. Similarly, manufacturers or commercial facilities can adjust their energy usage or utilize stored energy during times of peak grid demand, offering these valuable services to the energy market.

7. Demand Management and Peak Load Reduction

The real-time monitoring and control capabilities of process modeling software integrated with microgrids allow businesses to manage demand effectively. By shifting non-critical loads or utilizing stored energy from battery systems, companies can reduce their overall peak demand, avoiding costly demand charges during high-rate periods.

For energy-intensive industries like chemical manufacturing, glass production, or even data centers, managing peaks in energy use can result in significant cost savings. Process modeling software ensures that businesses optimize the timing of their energy consumption and prevent unnecessary grid dependency during expensive peak periods.

Applications for Key Industries

1. Chemical Plants

Chemical production requires uninterrupted energy for heating, cooling, and processing materials. A microgrid ensures a steady supply of energy while reducing the volatility of energy costs, helping businesses maintain competitiveness. By participating in grid services, chemical plants can also contribute to grid stability while optimizing their internal energy use.

2. Refineries

With strict safety regulations and high energy demands, refineries benefit significantly from energy storage systems that enhance operational stability. Microgrids improve energy efficiency, provide power during blackouts, and create revenue opportunities through grid service participation, reducing downtime risks.

3. Glass Manufacturing

Manufacturing glass requires a stable and consistent energy supply, particularly for the high-temperature furnaces used in melting raw materials. A microgrid with battery storage ensures that these energy needs are met even during power outages, while also offering the flexibility to engage in grid services like demand response, further enhancing cost efficiency and operational flexibility.

4. Data Centers and Commercial Facilities

Data centers and commercial buildings are becoming increasingly reliant on microgrids to ensure reliable energy and maximize cost efficiency. These facilities can also offer grid services by reducing load during peak demand periods, taking pressure off the main grid while benefiting from financial incentives.

Conclusion

For businesses that consume vast amounts of electricity, gas, and water, microgrids with battery storage present a strategic investment. They offer cost savings, improved reliability, enhanced sustainability, and operational flexibility, all while providing opportunities to participate in grid service markets and earn additional revenue. With advanced energy management systems, companies can fully optimize and control their energy usage, setting them up for long-term success in an increasingly energy-conscious and interconnected world.

By adopting microgrids and battery storage, chemical plants, refineries, glass manufacturers, data centers, and other energy-intensive industries can transform their operations—ensuring energy reliability, reducing costs, advancing their sustainability goals, and contributing to grid stability